RGV01-TF010203

OEM | ODM | WDS

| Availability: | |

|---|---|

| Quantity: | |

Worm Gear Resilient Seat PN25 Gate Valves | OEM Gate Valve Manufacturer

Tianjin Worlds Valve Co., Ltd. – ISO 9001, CE, UKCA & WRAS Certified Factory

RGV01-TF010203--Operation and Maintenance Manual DOWNLOAD

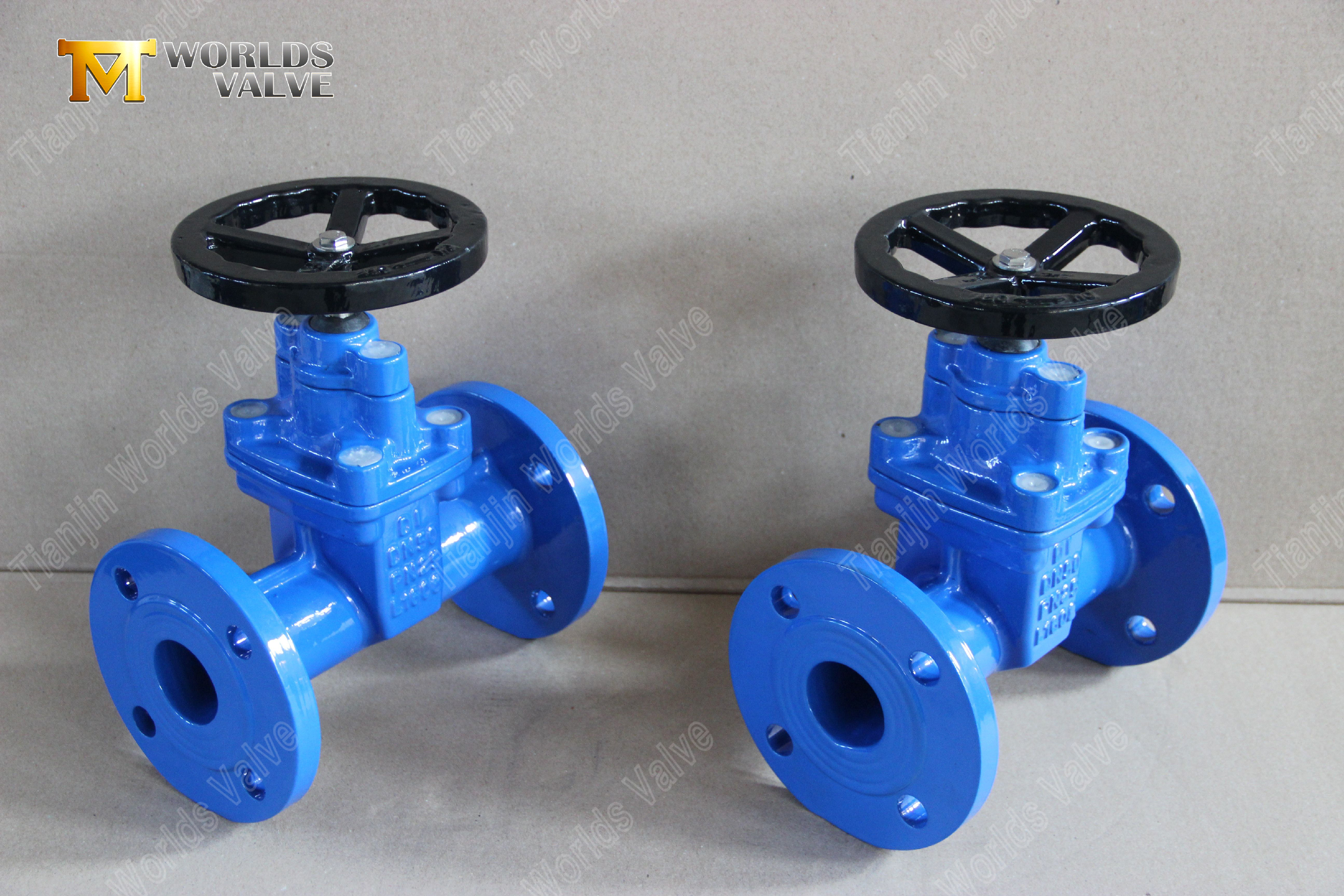

1. High-Pressure Resilient Sealing

Zero Leakage Performance: EPDM encapsulated wedge achieves EN 12266-1 Class A bubble-tight shutoff at PN25 pressure rating

Corrosion Prevention: Complete rubber-to-body contact eliminates metal-to-metal seating surfaces

Temperature Resilience: Maintains sealing integrity from -10°C to 120°C in continuous operation

2. Enhanced Material Construction

Reinforced Body Design: Ductile iron body with increased wall thickness to withstand PN25 working pressure

Corrosion Protection: 300μm fusion-bonded epoxy coating per AWWA C504 standards

Durable Internals: stainless steel SS431 stem with precision-machined trapezoidal threads

3. OEM Customization Capability

Size Flexibility: Available from 2" to 24" (DN50 to DN600) with custom face-to-face dimensions

Material Options: Alternative seat materials (NBR, Viton), special coatings, and branded components

Technical Support: Engineering assistance for application-specific modifications and testing

4. Maintenance-Friendly Features

Lubrication-Free Operation: Self-lubricating bronze bushings and sealed bearings eliminate routine maintenance

Easy Access: Removable gearbox cover simplifies inspection and service when required

Detailed Description: | |

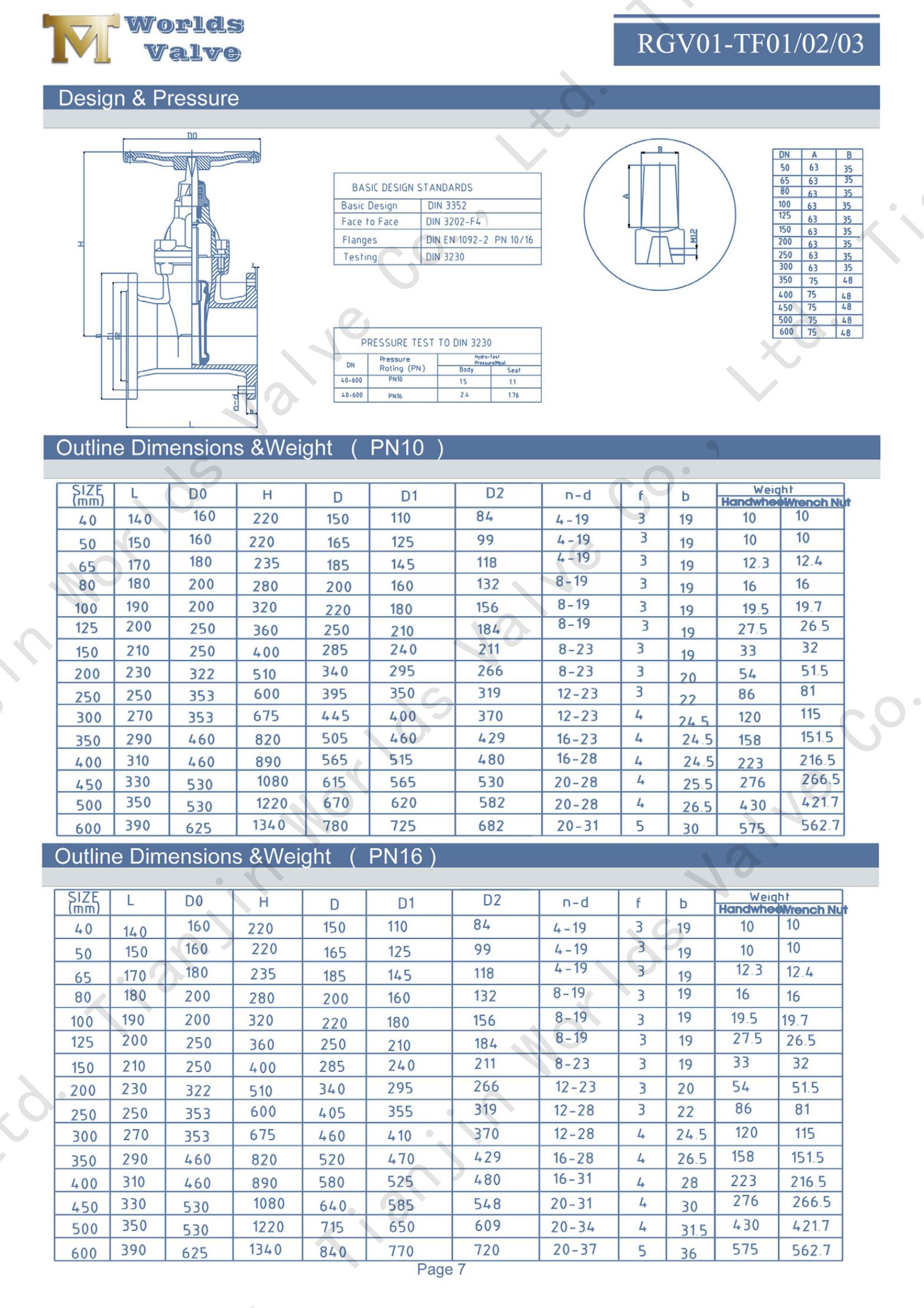

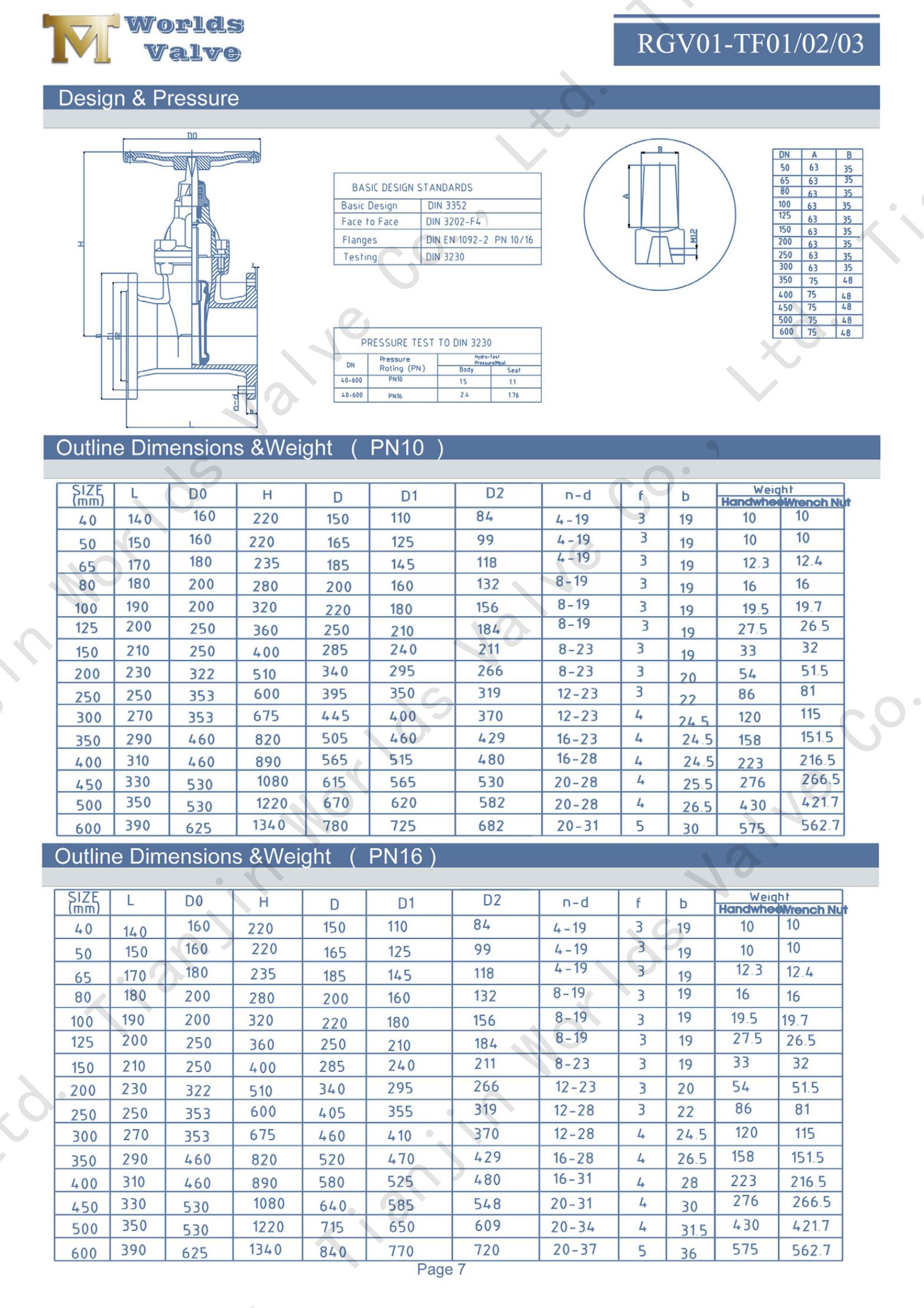

Series | Gear Operated Non-Rising Stem Gate Valve |

Size | DN40-DN600 |

Design Standard: | BS5163 DIN3352 BS EN 1171 API600 API6D AWWA C509 MSS SP-70 |

Face To Face: | DIN3202 F4/F5 BS5163 ASME/ANSI B16.10 AWWA C509 |

Fire Safe Design: | API 6FA |

Pressure Rating: | ASME/ANSI B16.34 |

Inspection & Test | API598 API6D ISO5208 |

Flange End: | ASME/ANSI B16.5 &B16.47 ASME B16.42 AWWA C207 ISO7005 DIN28533 DIN EN 1092 DIN2501 JIS B 2220 |

High-Pressure Capability: PN25 rating ensures reliable performance in demanding applications

Maintenance-Free Operation: Self-lubricating components and corrosion-resistant materials

Global Certification: CE, UKCA, and WRAS approvals for international project compliance

Custom Engineering: Flexible OEM solutions with technical support and quality assurance

Proven Durability: Robust construction tested to 38 bar for long-term reliability

Energy Efficiency: Low operating torque reduces manpower requirements and operational costs

High-Pressure Water Systems: Mainline isolation in municipal water distribution networks

Fire Protection: Sprinkler systems and hydrant supply lines requiring PN25 rating

Industrial Processing: Pump discharge control and process water lines

Irrigation Systems: High-pressure agricultural and landscape watering networks

Building Services: Riser mains and mechanical systems in high-rise constructions

Engineered for high-pressure applications, these worm gear resilient seat PN25 gate valves deliver unmatched performance and reliability for water distribution, fire protection, and industrial systems requiring robust flow control solutions.

Meeting Your Specific Needs:

Worm Gear Resilient Seat PN25 Gate Valves | OEM Gate Valve Manufacturer

Tianjin Worlds Valve Co., Ltd. – ISO 9001, CE, UKCA & WRAS Certified Factory

RGV01-TF010203--Operation and Maintenance Manual DOWNLOAD

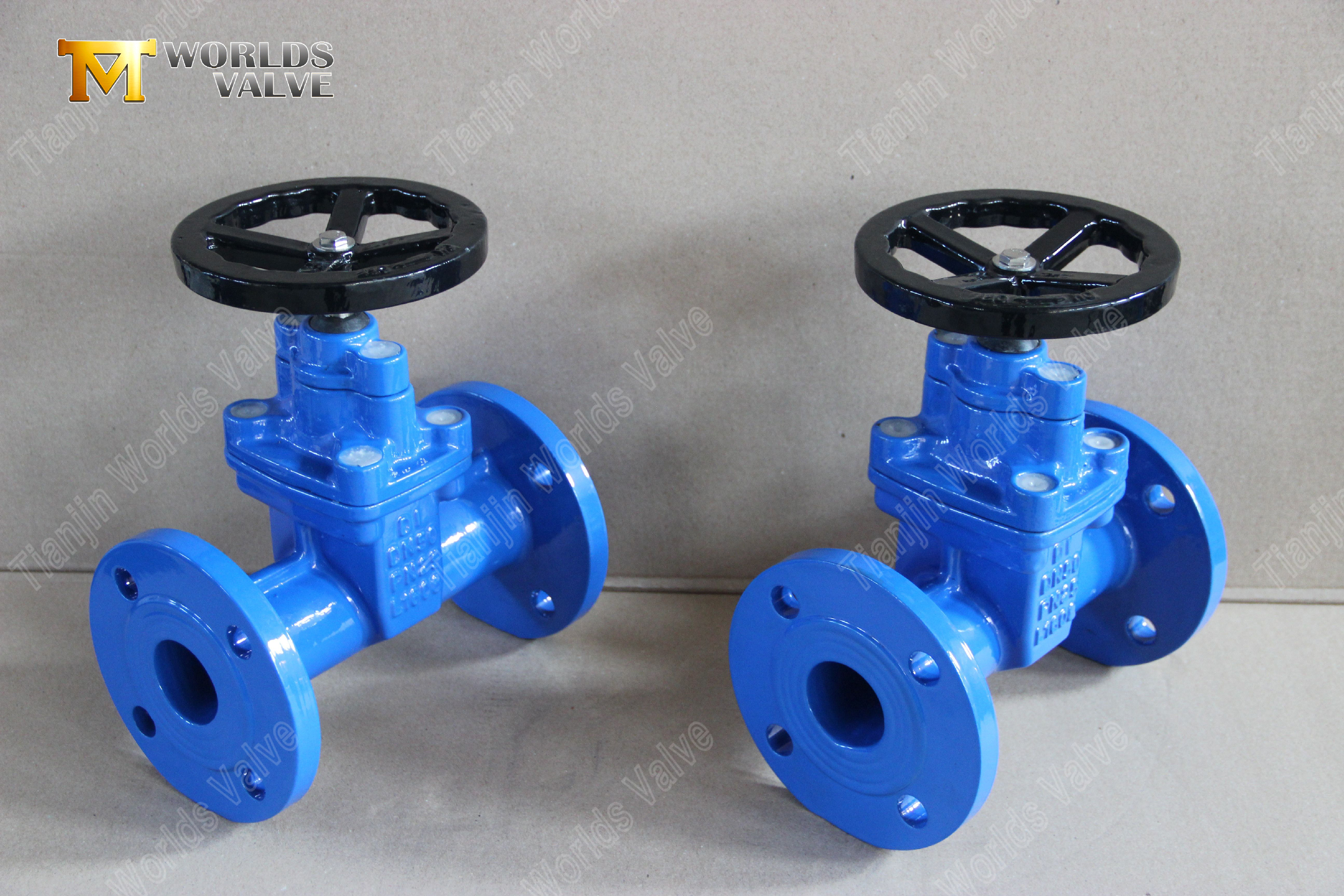

1. High-Pressure Resilient Sealing

Zero Leakage Performance: EPDM encapsulated wedge achieves EN 12266-1 Class A bubble-tight shutoff at PN25 pressure rating

Corrosion Prevention: Complete rubber-to-body contact eliminates metal-to-metal seating surfaces

Temperature Resilience: Maintains sealing integrity from -10°C to 120°C in continuous operation

2. Enhanced Material Construction

Reinforced Body Design: Ductile iron body with increased wall thickness to withstand PN25 working pressure

Corrosion Protection: 300μm fusion-bonded epoxy coating per AWWA C504 standards

Durable Internals: stainless steel SS431 stem with precision-machined trapezoidal threads

3. OEM Customization Capability

Size Flexibility: Available from 2" to 24" (DN50 to DN600) with custom face-to-face dimensions

Material Options: Alternative seat materials (NBR, Viton), special coatings, and branded components

Technical Support: Engineering assistance for application-specific modifications and testing

4. Maintenance-Friendly Features

Lubrication-Free Operation: Self-lubricating bronze bushings and sealed bearings eliminate routine maintenance

Easy Access: Removable gearbox cover simplifies inspection and service when required

Detailed Description: | |

Series | Gear Operated Non-Rising Stem Gate Valve |

Size | DN40-DN600 |

Design Standard: | BS5163 DIN3352 BS EN 1171 API600 API6D AWWA C509 MSS SP-70 |

Face To Face: | DIN3202 F4/F5 BS5163 ASME/ANSI B16.10 AWWA C509 |

Fire Safe Design: | API 6FA |

Pressure Rating: | ASME/ANSI B16.34 |

Inspection & Test | API598 API6D ISO5208 |

Flange End: | ASME/ANSI B16.5 &B16.47 ASME B16.42 AWWA C207 ISO7005 DIN28533 DIN EN 1092 DIN2501 JIS B 2220 |

High-Pressure Capability: PN25 rating ensures reliable performance in demanding applications

Maintenance-Free Operation: Self-lubricating components and corrosion-resistant materials

Global Certification: CE, UKCA, and WRAS approvals for international project compliance

Custom Engineering: Flexible OEM solutions with technical support and quality assurance

Proven Durability: Robust construction tested to 38 bar for long-term reliability

Energy Efficiency: Low operating torque reduces manpower requirements and operational costs

High-Pressure Water Systems: Mainline isolation in municipal water distribution networks

Fire Protection: Sprinkler systems and hydrant supply lines requiring PN25 rating

Industrial Processing: Pump discharge control and process water lines

Irrigation Systems: High-pressure agricultural and landscape watering networks

Building Services: Riser mains and mechanical systems in high-rise constructions

Engineered for high-pressure applications, these worm gear resilient seat PN25 gate valves deliver unmatched performance and reliability for water distribution, fire protection, and industrial systems requiring robust flow control solutions.

Meeting Your Specific Needs:

Selecting the right butterfly valve for your system is a crucial decision that can affect the performance and longevity of your piping network.

The Bare Shaft Double Flanged Butterfly Valve provides a fundamental and versatile flow control solution designed for seamless integration with any actuation system. Featuring an unfinished shaft extension and robust double-flanged construction, this valve serves as the ideal core component for customized automation across water, HVAC, and industrial processing applications.

The Wafer Type Soft Rubber Lined Butterfly Valve provides an economical and efficient solution for water treatment, irrigation systems, and general industrial services where reliable bubble-tight sealing and minimal maintenance are essential. This valve features a resilient rubber-lined design that ensures excellent sealing performance while maintaining a compact and lightweight profile for easy installation between pipeline flanges.

The PTFE Seat & PFA Coated CF8 Disc Butterfly Valve represents a premium solution for handling the most aggressive chemical media and ultra-pure processes. This valve combines a PTFE seat with a PFA-coated CF8 (SS304) stainless steel disc, creating an unparalleled barrier against corrosion, contamination, and chemical attack in critical industrial applications.

Choosing the right lug butterfly valve is key for safe, leak-free operation. Gaskets play a vital role in maintaining tight seals under varying pressures and temperatures. Tianjin Worlds Valve Co., Ltd. provides durable, high-quality valves that make installation easier, reduce maintenance needs, and deliver reliable performance for long-term industrial use.

Home | About Us | Products | Solutions | Certifications | Contact Us

No.25,Fuhui Road,Beizhakou Industrial Zone,Jinnan District ,Tianjin,China

Copyright By © Tianjin Worlds Valve Co.,Ltd.