CBF03-TA03

OEM | ODM | WDS

| Availability: | |

|---|---|

| Quantity: | |

Professional PN16 Wafer Butterfly Valve with Split-Stem Design

Tianjin Worlds Valve Co., Ltd. – Your Reliable Source for Durable, Cost-Effective Flow Control

CBF03-TA03-Operation and Maintenance Manual DOWNLOAD

1. Enhanced Structural Integrity with Split-Stem Design

Unlike conventional single-stem valves, our innovative dual-shaft (upper & lower) configuration delivers superior performance and durability.

Increased Strength & Rigidity: The split-stem system provides exceptional torsional strength, effectively resisting bending and deformation under high pipeline stress or pressure surges.

Precise Disc Alignment & Smoother Operation: This design ensures perfect, stable alignment of the disc during its entire 90-degree rotation, resulting in consistently smooth, low-friction operation and reduced actuator strain.

Extended Service Life: By minimizing mechanical stress and wear on the stem and bearing points, the design significantly prolongs the valve's operational lifespan and reduces long-term maintenance needs.

2. Optimized Material Selection for Maximum Durability

We pair premium materials for critical wetted components to ensure reliability in demanding environments.

Corrosion-Resistant Disc (CF8M/AISI 316): The valve disc is manufactured from CF8M stainless steel, which offers superior resistance to pitting and corrosion from chlorides, acids, and a wide range of chemicals compared to standard 304 grades, making it ideal for harsh or marine applications.

High-Performance Elastic Seat (EPDM): The ethylene propylene diene monomer (EPDM) seat provides excellent long-term sealing elasticity, strong resistance to water, steam, and weathering, and reliable performance across a broad temperature range from -20°C to 120°C.

Synergistic Longevity: The combination of a hard, corrosion-resistant disc and a resilient, sealing-elastic seat creates a robust interface that maintains a leak-tight seal over countless cycles with minimal degradation.

3. Reliable High-Pressure Sealing Performance (PN16 Rated)

Engineered to deliver secure shut-off in systems requiring higher pressure containment.

Bubble-Tight Seal Assurance: The precision-machined CF8M disc interacts perfectly with the elastic EPDM seat to create a reliable, bubble-tight seal, effectively preventing internal leakage and ensuring process integrity.

Stable Performance Under Pressure: The valve is rigorously designed and tested to perform consistently at its PN16 pressure rating, providing a dependable barrier against backflow and pressure loss in critical pipeline segments.

System Protection: This reliable sealing capability safeguards upstream equipment, prevents media mixing, and contributes to overall system safety and efficiency.

4. Cost-Effective & Space-Efficient Installation

The wafer-style design provides significant practical and economic benefits for system builders.

Compact, Lightweight Profile: The valve eliminates the need for a full flange body, resulting in a much lighter and more compact unit that simplifies handling and reduces structural support requirements.

Simplified Installation Process: Installation is quick and straightforward—the valve is simply centered between two pipeline flanges and secured with through-bolts. This eliminates the need for separate flange nuts or complex alignment procedures, drastically cutting labor time and costs.

Reduced Total Cost of Ownership: Savings are realized across multiple fronts: lower initial unit weight, reduced shipping costs, minimal installation labor, and less required space within the piping system.

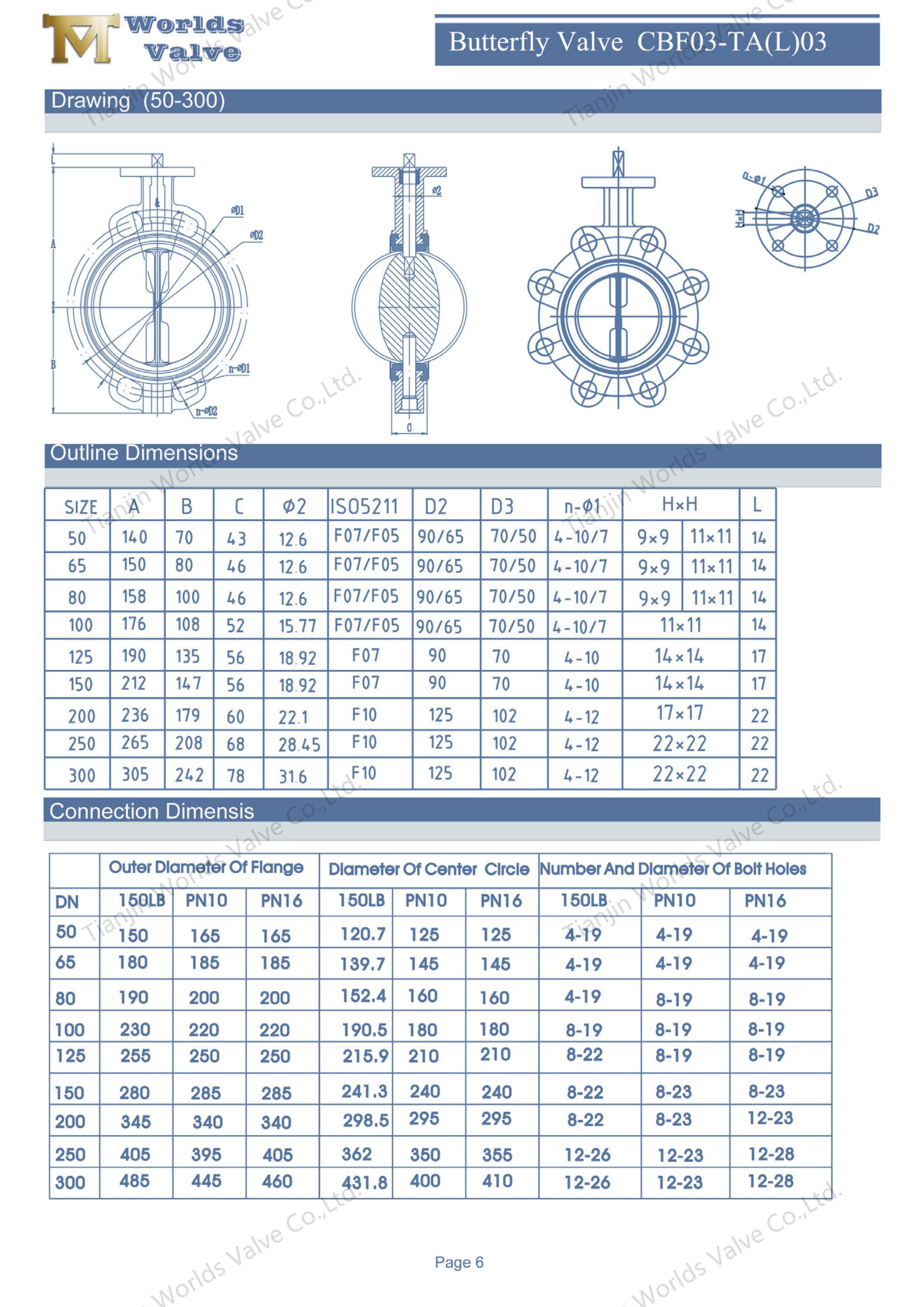

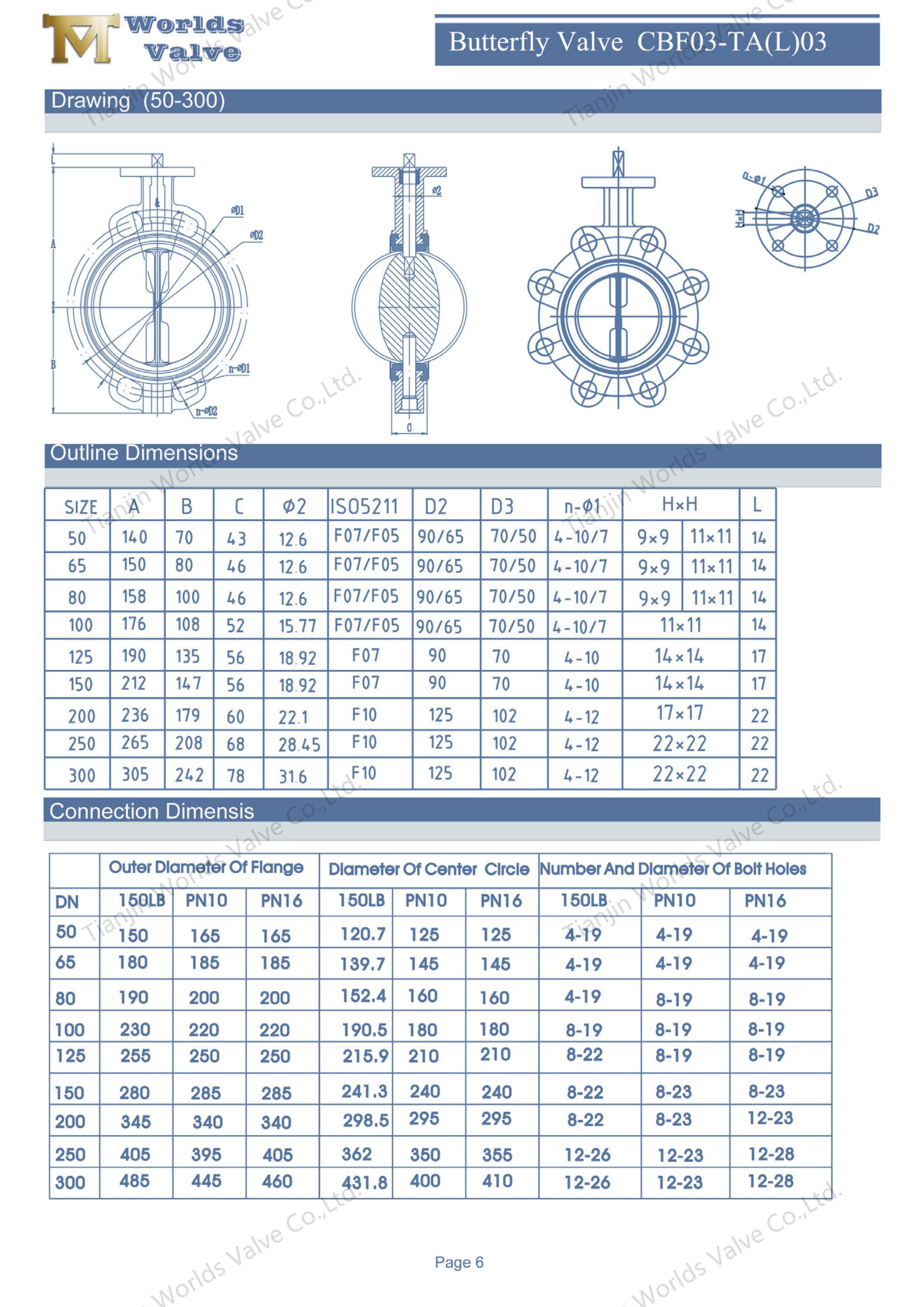

Parameter | Specification |

Model | Wafer Butterfly Valve(CBF03-TA03) |

Sizes | DN50-DN1200 |

Design | Split-Stem (Upper & Lower Shaft) |

Pressure Rating | PN6/10/16/150LB/JIS10K/AS “D”/ “E” |

Design | EN593 BS5155 EN1092 ISO5211 |

Testing | ISO5208 EN12266-1 |

TOP Flange | ISO5211 (according to customer’s needs) |

Face to Face | EN558-1 DIN3202 ISO5752 BS5155 |

Standard | ASME B16.34 |

Body | Ductile Iron |

Disc | CF8M (AISI 316 Stainless Steel) |

Seat | EPDM |

Stem | SS431 |

Certified Manufacturer with Global Compliance: We are an ISO 9001 certified factory, and our products are designed and tested to meet stringent international standards, including **WRAS, ACS, UKCA, and CE**. This ensures the quality, safety, and acceptability of our valves in markets worldwide.

OEM/ODM Expertise & Flexible Customization: As a specialist in OEM and ODM services, we offer more than just standard valves. We collaborate closely with clients to provide tailored solutions—whether in **size, pressure rating, material grade (e.g., CF8, CF8M, Ductile Iron), or special coatings**—to meet exact project specifications.

Proven Export Experience & Reliable Service: With a proven track record of exporting to dozens of countries across various continents, we possess rich international trade expertise. Our team provides end-to-end support, from technical consultation and documentation to timely logistics, ensuring a smooth and reliable supply chain experience for our global partners.

This valve is the workhorse solution for numerous industries requiring reliable and maintainable isolation:

Municipal Water Supply & Distribution Networks

Industrial Cooling Water & HVAC Systems

Wastewater Treatment & Pumping Stations

Fire Protection & Irrigation Systems

General Service in Chemical, Power, and Marine Industries

Looking for a reliable, certified supplier for your valve project? Contact Tianjin Worlds Valve Co., Ltd. today. Our team is ready to provide detailed product specifications, certifications, competitive pricing, and expert OEM/ODM support tailored to your needs.

Professional PN16 Wafer Butterfly Valve with Split-Stem Design

Tianjin Worlds Valve Co., Ltd. – Your Reliable Source for Durable, Cost-Effective Flow Control

CBF03-TA03-Operation and Maintenance Manual DOWNLOAD

1. Enhanced Structural Integrity with Split-Stem Design

Unlike conventional single-stem valves, our innovative dual-shaft (upper & lower) configuration delivers superior performance and durability.

Increased Strength & Rigidity: The split-stem system provides exceptional torsional strength, effectively resisting bending and deformation under high pipeline stress or pressure surges.

Precise Disc Alignment & Smoother Operation: This design ensures perfect, stable alignment of the disc during its entire 90-degree rotation, resulting in consistently smooth, low-friction operation and reduced actuator strain.

Extended Service Life: By minimizing mechanical stress and wear on the stem and bearing points, the design significantly prolongs the valve's operational lifespan and reduces long-term maintenance needs.

2. Optimized Material Selection for Maximum Durability

We pair premium materials for critical wetted components to ensure reliability in demanding environments.

Corrosion-Resistant Disc (CF8M/AISI 316): The valve disc is manufactured from CF8M stainless steel, which offers superior resistance to pitting and corrosion from chlorides, acids, and a wide range of chemicals compared to standard 304 grades, making it ideal for harsh or marine applications.

High-Performance Elastic Seat (EPDM): The ethylene propylene diene monomer (EPDM) seat provides excellent long-term sealing elasticity, strong resistance to water, steam, and weathering, and reliable performance across a broad temperature range from -20°C to 120°C.

Synergistic Longevity: The combination of a hard, corrosion-resistant disc and a resilient, sealing-elastic seat creates a robust interface that maintains a leak-tight seal over countless cycles with minimal degradation.

3. Reliable High-Pressure Sealing Performance (PN16 Rated)

Engineered to deliver secure shut-off in systems requiring higher pressure containment.

Bubble-Tight Seal Assurance: The precision-machined CF8M disc interacts perfectly with the elastic EPDM seat to create a reliable, bubble-tight seal, effectively preventing internal leakage and ensuring process integrity.

Stable Performance Under Pressure: The valve is rigorously designed and tested to perform consistently at its PN16 pressure rating, providing a dependable barrier against backflow and pressure loss in critical pipeline segments.

System Protection: This reliable sealing capability safeguards upstream equipment, prevents media mixing, and contributes to overall system safety and efficiency.

4. Cost-Effective & Space-Efficient Installation

The wafer-style design provides significant practical and economic benefits for system builders.

Compact, Lightweight Profile: The valve eliminates the need for a full flange body, resulting in a much lighter and more compact unit that simplifies handling and reduces structural support requirements.

Simplified Installation Process: Installation is quick and straightforward—the valve is simply centered between two pipeline flanges and secured with through-bolts. This eliminates the need for separate flange nuts or complex alignment procedures, drastically cutting labor time and costs.

Reduced Total Cost of Ownership: Savings are realized across multiple fronts: lower initial unit weight, reduced shipping costs, minimal installation labor, and less required space within the piping system.

Parameter | Specification |

Model | Wafer Butterfly Valve(CBF03-TA03) |

Sizes | DN50-DN1200 |

Design | Split-Stem (Upper & Lower Shaft) |

Pressure Rating | PN6/10/16/150LB/JIS10K/AS “D”/ “E” |

Design | EN593 BS5155 EN1092 ISO5211 |

Testing | ISO5208 EN12266-1 |

TOP Flange | ISO5211 (according to customer’s needs) |

Face to Face | EN558-1 DIN3202 ISO5752 BS5155 |

Standard | ASME B16.34 |

Body | Ductile Iron |

Disc | CF8M (AISI 316 Stainless Steel) |

Seat | EPDM |

Stem | SS431 |

Certified Manufacturer with Global Compliance: We are an ISO 9001 certified factory, and our products are designed and tested to meet stringent international standards, including **WRAS, ACS, UKCA, and CE**. This ensures the quality, safety, and acceptability of our valves in markets worldwide.

OEM/ODM Expertise & Flexible Customization: As a specialist in OEM and ODM services, we offer more than just standard valves. We collaborate closely with clients to provide tailored solutions—whether in **size, pressure rating, material grade (e.g., CF8, CF8M, Ductile Iron), or special coatings**—to meet exact project specifications.

Proven Export Experience & Reliable Service: With a proven track record of exporting to dozens of countries across various continents, we possess rich international trade expertise. Our team provides end-to-end support, from technical consultation and documentation to timely logistics, ensuring a smooth and reliable supply chain experience for our global partners.

This valve is the workhorse solution for numerous industries requiring reliable and maintainable isolation:

Municipal Water Supply & Distribution Networks

Industrial Cooling Water & HVAC Systems

Wastewater Treatment & Pumping Stations

Fire Protection & Irrigation Systems

General Service in Chemical, Power, and Marine Industries

Looking for a reliable, certified supplier for your valve project? Contact Tianjin Worlds Valve Co., Ltd. today. Our team is ready to provide detailed product specifications, certifications, competitive pricing, and expert OEM/ODM support tailored to your needs.

This article presents Tianjin Worlds Valve Co., Ltd. as a specialized manufacturer of high-quality butterfly valves for global industrial markets. It highlights the company's mission to provide precision-engineered flow control solutions, emphasizing key strengths such as uncompromising material integrity (using ductile iron, CF8M stainless steel), application-specific engineering for various valve types (resilient-seated, high-performance, lined), and flexible OEM/ODM customization services. The article underscores its commitment to certified quality (ISO 9001, CE, UKCA) and positions the company not just as a supplier, but as a reliability partner with decades of export experience to over 50 countries, supporting broader project needs with complementary gate and check valves.

This guide details the critical industrial applications of **gate valves**, focusing on their role in providing absolute isolation with minimal pressure drop. It explains their use in Oil & Gas, Power Generation, Water Treatment, Chemical, and Marine industries, covering key selection criteria like design (rising vs. non-rising stem), materials, and sealing types. The article highlights how **Tianjin Worlds Valve Co., Ltd.** supplies reliable, certified gate valves for global projects with OEM/ODM support.

This comprehensive guide explains the critical applications of butterfly valves across major industries. It highlights the valve's simplicity, compact design, and cost-effectiveness as key advantages. The article details specific uses in Water & Wastewater Treatment, HVAC Systems, Chemical/Petrochemical Plants, and Mining/Slurry Handling, explaining why butterfly valves excel in each sector. It also covers specialized configurations for dead-end service and large-diameter pipelines, and provides essential selection and maintenance tips for optimal performance. The conclusion emphasizes the valve's versatility and introduces Tianjin Worlds Valve Co., Ltd. as a reliable, ISO9001-certified global manufacturer offering a complete range of standard and customized butterfly valve solutions, supported by international certifications and decades of export experience.

This article provides a comprehensive guide to the fundamental operating principle of check valves, which are essential for allowing fluid flow in only one direction and preventing costly backflow. It details the mechanics of common valve types, with a special focus on the advantages of the compact and efficient Dual Plate Wafer Check Valve. The guide further outlines key factors for selecting the right valve and highlights the expertise of Tianjin Worlds Valve Co., Ltd. As a specialist manufacturer with international certifications (CE, UKCA, ACS, WRAS), Worlds Valve offers reliable, customizable solutions and expert support for a global clientele across diverse industries.

This comprehensive guide details the five essential design pillars that distinguish a high-quality butterfly valve: disc design and material, seat sealing performance, body and connection construction, stem integrity, and bearing/actuation systems. It explains how these features directly impact valve lifespan, reliability, and total cost of ownership. The article also provides a practical pre-purchase checklist for engineers and buyers, covering pressure ratings, material compatibility, certifications, and supplier support. Highlighting the expertise of Tianjin Worlds Valve Co., Ltd., it illustrates how their certified, customizable butterfly valves are engineered to meet demanding global industrial standards.

Home | About Us | Products | Solutions | Certifications | Contact Us

No.25,Fuhui Road,Beizhakou Industrial Zone,Jinnan District ,Tianjin,China

Copyright By © Tianjin Worlds Valve Co.,Ltd.